One might assume that the importance of Decision Quality is a given in the oil and gas industry. The concept chosen in the assess and select phases can result in a great return, loss or missed opportunity; with the figures involved rarely below tens of millions, and sometimes rising to billions.

Despite its importance, it’s all too easy for Decision Quality to fall short of what’s needed. Decisions in oil and gas are highly complicated and susceptible to both cognitive and motivation-based bias. Even when you have a clear process to help overcome this, it’s possible for the process to contain gaps or not be upheld. This can happen for several reasons.

- There’s no one directly responsible for Decision Quality at each stage of a project. Or at least no one with the confidence, experience and clout to say when an element of decision-making isn’t the quality the company needs it to be.

- Decision Quality is not ingrained in the culture of the organisation. Often because there’s simply not been enough training on how to apply Decision Quality principles in context.

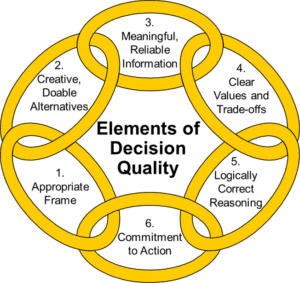

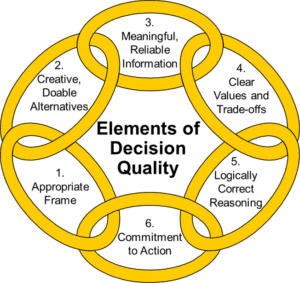

- There’s a lack of knowledge or experience regarding a critical link in the Decision Quality chain (see below), whether that’s how to align stakeholders or how to acquire meaningful and reliable information. Experience to drive every link in the chain to the right level of quality.

Like any chain, Decision Quality is only as strong as its weakest link. But with intentionality and practice, an oil and gas company can learn to collaborate to make better and better decisions, resulting in more consistent, high quality outcomes.

So let’s look at the six links in the chain in turn, and consider the importance of each one:

1. Clear and appropriate frame

Complex decisions in large organisations can only be made with quality if the key people involved discuss and agree the purpose and scope with real clarity.

For instance, when deciding on the concept for developing a field, is it in-scope to consider whether you could realise more value by selling all or part of the opportunity to another firm?

It’s vital for this frame to be agreed on by key internal stakeholders. Often it’s valuable to get input or test the frame with JV partners.

2. Creative and doable alternatives

To ensure Decision Quality, you cannot be wedded to one solution, no matter the circumstances. For example, we’ve seen situations in the past where teams have hung on the words of charismatic executives only to misinterpret a throwaway idea as a directive from on high. As a result, they didn’t weigh other ideas properly, and they selected a concept that sank the project.

To stay smart here, you have to realise you need to draw on the full expertise and experience of the team and challenge standard thinking. This will help to explore and push the boundaries of the project from a technical, commercial, stakeholder, and technology perspective. Evaluating a diverse set of well structured alternatives is a highly valuable step in the process.

3. Meaningful and reliable information

Once you have a range of alternatives to explore, you can investigate cost, time to build, environmental and social impacts, strategic and political fit, as drivers of value vs risk.

Getting clear on the full hierarchy of decision criteria based on the framing step helps prioritise several elements – the study work that needs doing, what data to collect and by when – so you can differentiate between alternative concepts in a cost and time efficient way. This is often a tiered selection process: the macro scale elements of project decision scope are taken first, followed by lower order smaller scale elements in a natural sequence.

The key to this Decision Quality link is not information, but meaningful and reliable information. A quick learning cycle helps you focus on what really matters. This is so that you’re not wasting time and money on the information that has little impact, or on trying to reduce irreducible uncertainty.

You also need to know when to stop collecting data. There will always be residual uncertainties, and the goal is not to eliminate them but reduce them to an acceptable level. Understanding the impact uncertainties have on value and risk can be used to guide effort. This will depend upon the frame that you agreed upon in the first link of the Decision Quality chain.

4. Clear values and tradeoffs

Once you have clear and meaningful information, your stakeholders can compare concepts, weighing the risk and potential reward of each one. Naturally, there will be some criteria that you care about more than others.

But at this point in the Decision Quality chain, things fall apart if the stakeholders weren’t aligned upfront on scope of decisions in the choice frame. For instance, a refurbished vs a new-build FPSO might be a trade-off between lower up-front capex vs lower long-term opex. If your internal stakeholders are divided on which is more important, you might find yourself at a stalemate or ‘stuck’ opportunity.

5. Logically correct reasoning

This final check of the plans is designed to unearth any unnoticed assumptions or flaws in the calculations and thinking, and external quality assurance can play a key role here.

Crucially, you also need to consider how dependencies factor in so you don’t miscalculate the risk. Independent variables are relatively simple to compare one against the other, but uncertainties around foundational elements of the concept design can tip the potential risk into ‘house of cards’ territory. Naturally you want to identify this before you greenlight. Decision makers need to have confidence in the analysis and insights that they are presented with when making trade-offs between alternatives.

6. Commitment to action

Commitment to action is essential to get projects off the ground. You don’t want to get to the sign-off stage of a project and for one of the decision makers to instead hit pause and ask to investigate further questions and avenues.

By involving these decision-makers along every link of the Quality Decision chain, you can head these concerns off early, and ensure that Quality Decision doesn’t slip into indecision.

So is that all you need to know?

It’s worth noting that the Decision Quality is not necessarily the holy grail, and it’s only a part of what makes for best practice. That said, it’s a critical part. So we’ll be returning to the subject in due course, taking you through why applying Decision Quality principles is difficult, and how you can get it right.

For now, if you’d like to explore more on best practice around decision making, see our articles on how to tell if your field development plan is ready to progress, as well as how you can make quality assurance more consistent, reliable and effective.